Using synthetic mooring tails is the most common method of decreasing loads in the mooring system. Tails are typically used with our UHMWE rope and steel wire rope to improve mooring system in integrity by reducing mean and peak loads. When used, tails serve as an integral part of the mooring system and should not be considered a weak link with the system’s design.

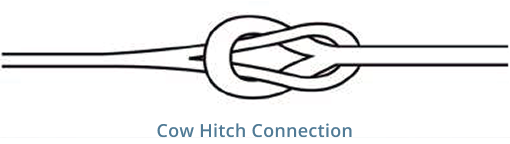

After properly installing the mooring lines on the winch drum, the tails should be attached to the working end of the mooring line. This is done by cow hitch connection per MEG4 guidelines.

The Tail Design Break Force (TDBF) needs to be higher than the LDBF, because the tail experiences more wear in service than line.

The TDBF of tails should be 125%-130% of ship design MBL.

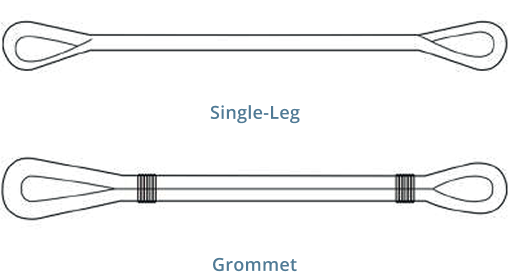

| Dia (mm) | Circ (ins) | Linear Density (Ktex) | Weight (KG/100mtr) | MBL / Single (KN) | Grommet (KN) |

|---|---|---|---|---|---|

| 48 | 6 | 1420 | 142 | 56.20 | 89.92 |

| 52 | 6-1/2 | 1700 | 170 | 65.90 | 105.44 |

| 56 | 7 | 1970 | 201 | 75.60 | 120.96 |

| 60 | 7-1/2 | 2260 | 226 | 86.40 | 138.24 |

| 64 | 8 | 2570 | 257 | 97.30 | 155.68 |

| 72 | 9 | 3270 | 327 | 122.40 | 195.84 |

| 80 | 10 | 4030 | 403 | 149.40 | 239.04 |

| 88 | 11 | 4860 | 486 | 180.40 | 288.64 |

| 96 | 12 | 5790 | 579 | 212.90 | 340.64 |

| Dia (mm) | Circ (ins) | Linear Density (Ktex) | Weight (KG/100mtr) | MBL / Single (KN) | Grommet (KN) |

|---|---|---|---|---|---|

| 48 | 6 | 1110 | 111 | 42.90 | 68.64 |

| 52 | 6-1/2 | 1320 | 132 | 49.80 | 79.68 |

| 56 | 7 | 1520 | 152 | 57.40 | 91.84 |

| 60 | 7-1/2 | 1750 | 175 | 66.00 | 105.60 |

| 64 | 8 | 1990 | 199 | 74.00 | 118.40 |

| 72 | 9 | 2520 | 252 | 93.00 | 148.80 |

| 80 | 10 | 3110 | 311 | 113.00 | 180.80 |

| 88 | 11 | 3750 | 375 | 136.00 | 217.60 |

| 96 | 12 | 4470 | 447 | 161.00 | 257.60 |