a high-quality UHMWE rope product used for the most demanding mooring, towing, and lifting applications.

The advanced equipment from Germany and Denmark and the mature technology in rope manufacturing account for its high quality and stability.

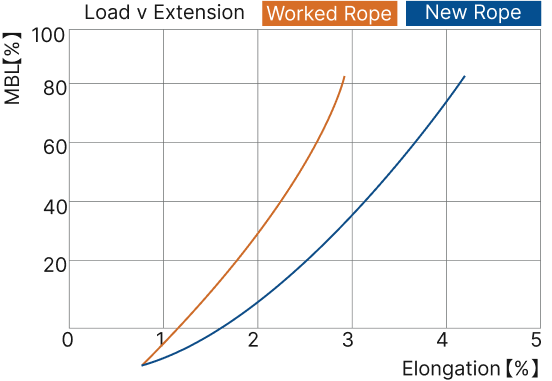

MAX® rope is your optimal choice for diversified mooring applications for its properties of high strength, excellent abrasion resistance, high strength-to-weight ratio, extremely low elongation and superior flex fatigue resistance.

| Dia (mm) | Circ (ins) | Linear Density (Ktex) | MBL (KN) Unspliced Rope | MBL (KN) Eye-Spliced Termination |

|---|---|---|---|---|

| 20 | 2-1/2 | 233 | 380 | 340 |

| 22 | 2-3/4 | 280 | 450 | 405 |

| 24 | 3 | 331 | 520 | 470 |

| 26 | 3-1/4 | 386 | 600 | 540 |

| 28 | 3-1/2 | 445 | 685 | 615 |

| 30 | 3-3/4 | 508 | 775 | 700 |

| 32 | 4 | 575 | 865 | 780 |

| 34 | 4-1/4 | 646 | 965 | 870 |

| 36 | 4-1/2 | 722 | 1070 | 965 |

| 38 | 4-3/4 | 801 | 1175 | 1060 |

| 40 | 5 | 884 | 1285 | 1155 |

| 44 | 5-1/2 | 1062 | 1525 | 1375 |

| 48 | 6 | 1255 | 1775 | 1600 |

| 52 | 6-1/2 | 1464 | 2045 | 1840 |

| 56 | 7 | 1688 | 2330 | 2095 |

| 60 | 7-1/2 | 1928 | 2635 | 2370 |

| 64 | 8 | 2183 | 2950 | 2655 |

| 68 | 8-1/2 | 2453 | 3285 | 2955 |

| 72 | 9 | 2738 | 3635 | 3270 |

| 76 | 9-1/2 | 3038 | 4000 | 3600 |

| 80 | 10 | 3353 | 4375 | 3940 |

| 88 | 11 | 4028 | 5180 | 4660 |

| 96 | 12 | 4762 | 6040 | 5435 |

| 100 | 12-1/2 | 5151 | 6495 | 5845 |

| 104 | 13 | 5555 | 6960 | 6265 |

| 108 | 13-1/2 | 5973 | 7440 | 6695 |

| 112 | 14 | 6406 | 7935 | 7140 |

| 116 | 14-1/2 | 6854 | 8440 | 7595 |

| 120 | 15 | 7316 | 8960 | 8065 |

| 124 | 15-1/2 | 7792 | 9495 | 8545 |

| 128 | 16 | 8283 | 10045 | 9040 |

| 132 | 16-1/2 | 8788 | 10605 | 9545 |

| 136 | 17 | 9308 | 11180 | 10060 |

| DIA (mm) | LDBF (mt) | LD (kg/m) | LBLD (kg/m) |

|---|---|---|---|

| 24 | 47.96 | 0.331 | 0.331 |

| 26 | 55.10 | 0.386 | 0.386 |

| 32 | 79.59 | 0.575 | 0.575 |

| 36 | 98.47 | 0.722 | 0.722 |

| 40 | 117.86 | 0.884 | 0.884 |

| 44 | 140.31 | 1.062 | 1.062 |

| 48 | 163.27 | 1.255 | 1.255 |

| 52 | 187.76 | 1.464 | 1.464 |

| 56 | 213.78 | 1.688 | 1.688 |

| 64 | 270.92 | 2.183 | 2.183 |

| 68 | 301.53 | 2.453 | 2.453 |

Mark:

LDBF: Line Design Break Force

LD: Linear Density

LBLD: Load Bearing Linear Density.

The product has been manufactured, tested following the guidelines in appendix B of the mooring equipment guidelines, Fourth edition (MEG4 2018).

Applications:

Mooring/ Towing/ Platform Fixing/ Defense Industry/ Port Handling and Other Mooring Related Purposes. MSS could supply the exclusive customized services of mooring tail and adjustable sheath.

The MAX® sling can be overbraided with high strength polyester jacket. The polyester jacket is very durable with excellent abrasion and cut resistance. Will protect the main sling line.

The sleeve is made of PVC and polyester, this sleeve can prevent sand and other small, hard object into main sling line.

Rope protection sleeve sewed with hook and loop tapes which can cove and uncovered easily

The coating material si polyurethane which can make the eye much stable and abrasion resistant.